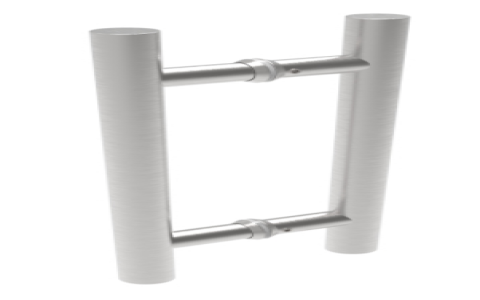

Stainless steel handrail bracket maintenance instructions and maintenance measures

A, the quality of common problems:

1, the pipe surface brightness is not enough, dark color, titanium-plated pipe surface color difference.

2, railing handrail bracket overall stiffness is not enough, hand clapping handrail bracket has a trembling feeling.

3, the column is not vertical, the arrangement is not in the same line, shaking is not solid.

4, handrail bracket bend is not smooth.

5、There is a gap at the pipe connection.

6、Circular arc handrail bracket arc is not smooth, there is demolition prism.

7、The wall of the welded seam is worn through, and the polish is not enough.

8、The surface has scratches and pits.

9, stainless steel handrail bracket glass fixed problem.

Second, preventive measures

1, first of all, we must choose the quality of qualified pipe. ?Different grades of pipe with different elements, even in the same factory titanium plating, the surface color of the finished product also has color differences. Therefore, attention should be paid to the use of the same category and grade of stainless steel pipe, and should strengthen the quality management of titanium plating process.

2, due to the selection of the wall is too thin, so that the overall strength is not enough, should be selected with a wall thickness greater than or equal to 1.2 mm of the pipe to do handrail bracket. The diameter of the pipe should not be too small, when the length of the straight section of the handrail bracket is long, the design of the column should have lateral stability strengthening measures.

3、Inaccurate bullet line, improper installation method. ?Construction must be accurate line, first use the level to correct both ends of the benchmark column and fixed, and then pull through the line according to the positioning of each column will be fixed. ?Before welding should be strengthened to check the pre-buried parts, found that there are problems with the buried rod should be reinforced. ?Should prevent the fixed column base expansion bolt is too short, or finish stone under the cement mortar layer is not full. ?Should strengthen the quality inspection of each construction process, in order to correct quality problems in a timely manner.

4, processing technology is not high. Should use the professional factory production of right-angle elbow, non-standard angle elbow, according to the construction of the detailed drawing of the release of special processing, processing plant should have special production equipment.

5, welding should be full welding. The best use of lined casing.

6, due to the selection of the pipe wall thickness is too thin, easy to occur in the processing of the elbow deflated, and make the tube is not round, in the butt welding and no liner casing, so that after welding grinding flat weld, easy to bulge one end of the pipe wall grinding through, should choose the appropriate thickness of the pipe, the best additional liner casing when welding.

7、Improper protection of finished products, collision with objects in the cross operation, scratch. The construction process should be reasonably arranged, and finally the handrail bracket installation should be carried out at a later stage. ?Protection and isolation of the completed handrail bracket, to prevent collision and scratching of foreign objects.

8, stainless steel handrail bracket, consider the weight of the railing, glass clip to choose the right, and pay attention to the fixed solid.